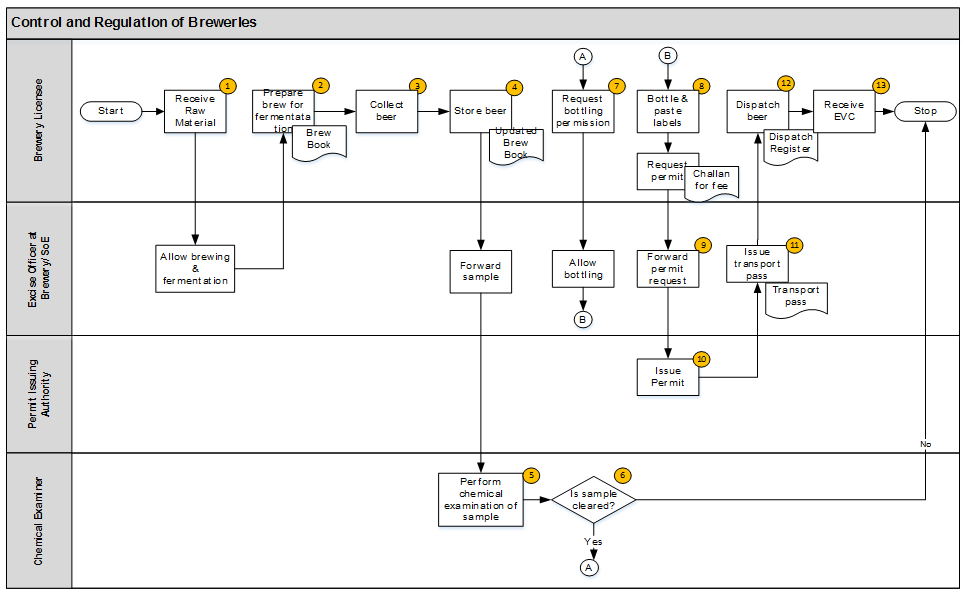

Process Description

| Process Particulars | Details |

|---|---|

| Process Name | Control and regulation of Brewery |

| Process Objective | Monitoring the Production of Beer |

| Process Owner | Excise Officer |

| Process Participants | License (Brewery), Excise Officer/SoE, Permit Issuing Authority, Chemical Examiner |

Input

| No | Description | Format | Supporting Documents | Source |

|---|---|---|---|---|

| 1 | Brew Book | Prescribed format | NA | Licensee, Excise Officer |

As-Is Process

Output

| No | Description | Format | Supporting Documents | Destination |

|---|---|---|---|---|

| 1 | Permit | Prescribed format | none | Licensee, Excise officer |

| 2 | Transport pass | Prescribed format | none | Licensee, Excise officer |

Key Challenges & Process Gaps

| Sr. No. | Process Step | Process Description | Remarks/Challenges |

|---|---|---|---|

| 1 | Raw material receipt | Raw material is received by licensee. | Excise officer does not monitor raw material receipts through the registers. |

| 2 | Preparation of brew | Brew is prepared in designated tank/vat for registered brand. | Manual register i.e. brew book is maintained for records. |

| Excise officer monitors the registers. | |||

| Standard process is followed for production of beer. | |||

| Brew's batch number is assigned by the licensee. | |||

| 3 | Collecting beer | Produced beer is collected in Bright Beer tank | Produced beer is collected in vat and brew book is updated. |

| Manual register are prone to errors and difficult to cross-reference & reconciliation. | |||

| Allowable losses are not linked to operational characteristics of the unit appropriately. | |||

| There is limited visibility into the yield. | |||

| 4 | Storage of beer | Spirit is stored in storage vat | Beer is stored in storage vat and the same is updated in the register. |

| Manual registers are prone to errors and difficult to cross-reference & reconciliation. | |||

| Monitoring of losses and penalties for losses beyond allowed limit are difficult using manual records. | |||

| 5 | Chemical examination | Sample of beer is received by chemical examiner's office for testing | Produced beer is subjected to chemical testing by Chemical Examiner's office before bottling. |

| Sample collection is not monitored/recorded by the excise officer. | |||

| There is only one chemical examiner's office to which all similar units send the samples for testing. | |||

| 6 | Result of chemical examination | Chemical examination report is shared. | Submission of sample and sharing chemical examination report is manually done, which is prone to errors and delays. |

| Process for samples/production failing chemical examination could not be ascertained. | |||

| 7 | Bottling request | Bottling is done with approval of the excise officer. | Bottling requires acceptable report of samples from Chemical Examiner's office. |

| Licensee is required to collect permission from excise officer before starting bottling, labelling and packing. | |||

| 8 | Bottling of beer | Beer is bottled and packaged products are put into cartons/boxes/cases. | Bottling records are updated manually which is prone to errors and mistakes. |

| 9 | Request for permit | Permit is requested from CoE to transport/export beer | Licensee requests for permit for transport/export of beer from CoE through excise officer of the distillery which is a lengthy process. |

| To export the products, licensee is required to produce import permit from destination state to get permit from DoE, Assam. | |||

| 10 | Forwarding permit request | Excise officer forwards permit request | Monitoring of forwarded permit requests not done by excise officer. |

| 11 | Grant of permit | CoE grants permit for transport/export of beer | Manual process of issuing permits is followed and no transport permit register is maintained. |

| 12 | Issue of transport pass | Based on permit, excise officer issues transport pass | No register is maintained for issued transport passes by excise officer. |

| Reconciliation of records is difficult due to manually kept records. | |||

| 13 | Beer despatch | Licensee despatches spirit along with the transport pass | Licensee despatched the spirit and updates the despatch register with permit & transport pass details. |

| Beer from storage vat is despatched by tanker and storage register is updated. | |||

| Manual registers are maintained for records. | |||

| Excise officer monitors the registers. | |||

| 14 | Excise verification certificate (EVC) | EVC from excise officer of the beer receiving unit is required | Manually prepared EVC and manually prepared records make it difficult |

| Beer losses in transit is difficult as no register for EVCs is maintained. |

Process Timeline

No timelines for the process completion is defined or that between two consequent steps found to be prescribed or defined. Production & despatch is also dependant on the business requirement of the licensee. There is limited visibility into the yield of the grain based production. There are multiple registers to be maintained, with some parts of information being repeated across registers. Maintaining all records manually is tedious and prone to errors and extracting information to establish a pattern in timeline is difficult.